The short to medium automotive future is Hybrid, not electric

Why Full Electric Cars are not competitive at all with conventional thermal engines, and in particular with diesel?

Full Electric car are the latest innovation in the transport market.

✓ They are fantastically promoted by any kind of media and politic speech,

✓ They are indicated like the technology answer to the problem of the greenhouse gases and noxious emissions.

✓ They are contributing even in reducing the effect of the viruses: the last discovers proves that the viruses like COVID19 are spread much more easily in presence of fine powders in the air (PM10), as known, generated by combustion of diesel, gasoline engines (in reality PM10 are mainly generated by road surfaces scratch by the heavy cars use).

✓ They have beautiful names like Tesla (exploiting the name of the genius Nikola Tesla), Taycan, i3 (like intelligent 3), etc….

✓ They have fantastic acceleration (really!!)

✓ They are perfect in the sprint races

BUT as cars of everyday use, I think they are not encountering the expected success.

We are sorry to be out of the mainstream opinion, but really, full electric car are and will be a huge flop.

WHY??? Because…. have you ever seen a Full Electric car always on the fast line in the highway in Italy or Germany? No? Maybe there is a reason for that…

To be clear: 30 minutes of refuelling in super charger is simply too much, moreover you will not get 100% of battery but more or less half of the maximum range.

Professionals travelling on the highway have to run to work and doing businesses, they cannot waste 30 minutes of precious time at the recharging station every 150-200km.

Moreover imagine you arrive home after a busy day and your brand new 100.000 euros Full Electric SUV is empty. You attach your car to the charger in garage and suddenly you realize that you forget too buy something (or, even worst, you have an emergency) … then? What are you doing?

YOU CALL A TAXI!!! Because your brand new SUV is like a useless furniture.

We have driven and used several times Teslas, BMW i3, Porsche Taycan, so we exactly know what we are writing: the currently produced full electric cars are extremely performant in term of acceleration, reduction of local emissions and noise, but these electric cars are still ages far away from the freedom of use and practicality of a diesel car, that you can refuel everywhere, in 5 minutes, every 1000km.

This fact happens for two main reasons:

1- the energy density in the best battery in the market is 20 times lower then fossil fuel. It means that at 130 km/h in normal traffic driving conditions, with a kg of fully charged battery you drive for 1km, while with a kg of diesel you drive for 20km

2- the recharging time are sooooo long, and the fast charge at supercharger is not giving you the same autonomy of the 9 hours recharging at home (exactly like your iphone).

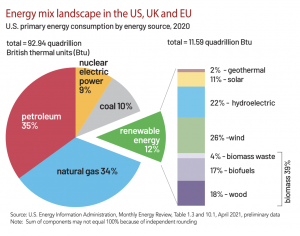

3- the infrastructure and manufacturing of the cars are all but green and not yet enough developed in terms of efficiency and sustainability

Coming back to the car, the problem is that the tests on road of range are always made in the perfect condition to show off performances difficult to reproduce in the real conditions. In fact serious on-road tests are highlighting the criticality of the FEV (full electric vehicle) range in real use conditions. Imagine: you are stuck in a queue on the highway, it is raining and you have air conditioning on (conditions quite typical in Europe), you are really in the nightmare worst condition for your battery.

Despite the fact that the industry is working to improve the battery packs efficiency and the EVs performances and, in the meantime, the charging infrastructures are increasing, still medium-long distances are difficult to cover, and even the latest rapid charge time are not fast enough for an efficient and convenient use of the car.

Furthermore, beside the real potential EVs performances, the range anxiety is a factor which cannot be ignored, and surely negatively influences the EVs market penetration. A lot of promotion is currently bombarding users about the advantages of the use of a full electric car, but in reality only users living in big towns and having an urban profile use could benefit from a full electric car, without a lot of stress. But for the users that need flexibility and urban and both extra urban profile use the full electric is not yet viable at all.

This is why our effort are mainly focused on two directions:

- The short to medium terms efforts are targeted on the hybrid technology, Hydrogen and sustainable fuels. These solutions are merging together the advantages of the conventional thermal engines, the next generation of electric motors, the energy harvesting systems.

- The medium to long term mass commercialisation for the full electric cars is totally relied on the application of the principle of Life Cycle Engineering specifically on batteries and energy production and infrastructures.

This seems to be the correct answer for the today and incoming future of the cars. With the hybrid engine you can run in the highway as usual, you refuel your car in 3 minutes, you drive in the center of the town in full electric mode, you can use your air conditioning, and, if you want, you can also listen to…. the engine sound!!!

Our first worldwide hybrid rally car for Ice Racing, 2017. 630 HP combined, 0-100 in 1.5s, almost same weight of thermal car. Winner of the Ice Challenge International Championship 2018